6th November 2017.

One of the big jobs around the motion is the extraction of the wedges that secure the crossheads to the piston rods. This is achieved by welding a screw thread to the top of the wedge and then using a 'bridge' against which a nut is tightened to extract the wedge. Serious force is required to start the release but once the initial grip was broken, the RHS came out quite smoothly. The LHS fought all the way and when finally out, the wedge was seen to be 'banana' shaped. Inspected later in the day by a visting engineer, he opined that it was the result of priming in the LH cylinder, confirmed (he said) by the 'step' that could be felt at the leading edge of the hole through the crosshead/psiton rod.

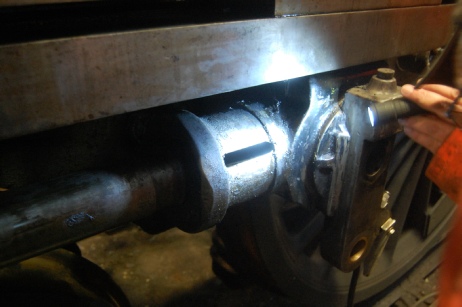

The second part of this job is to release the taper-pin seating of the end of the piston rod in the crosshead. The prescribed method for this task is to use a special hydraulic tool but, in preservation, it's become common to use either a button/wedge combination or a screw through an old gudgeon pin. In preparation for the second of these, a suitable screw has been machined for use next week.

A bit of tidying up around the outside of the cylinders has been done - the final section of cladding was removed by new-boy Roger and the remaining fittings have been taken off the cylinders by the front-of-chassis team - supports for the pressure relief drains that run down from the piston valves.

Under the footplate, battle commenced with the bracket that holds the hinge for the brake actuation. Brute force (Philip, with Ian & David) removed the first 2 (of 16) bolts and, on Sunday, Alan used heat and force to take out a further 4. That leaves two outers to come off, then a very difficult-looking 8 internal bolts - these might be simply burned off. What can be seen of the drag-box under the (now removed) steam-brake cylinder and around the hinge bracket is giving some cause for concerned - it looks very corroded and thin in places.

Outside on the boiler, at the front end, StanD and Dennis have been knocking soot and scale and rust out of the insides of the superheater flue ends to ease the job of the oxy-acetylene cutting that is needed to remove those tubes. Inside the firebox, very good progress has been made removing the soot and exposing the copper of the inner box. The insurance NDT of the boiler is scheduled for Tuesday November 28th, so we've a couple more weeks to be as ready as we can be for that.

October 2017

October 2017