Nene Valley Railway, Wansford Station, Stibbington, Peterborough, PE8 6LR

12th April 2017.

Work continues removing boiler-attached parts.

To ease access and visibility, the loco is moved out into the yard. It can be seen that part of the LHS running board and the front LHS steps have been detached.

What can’t be seen is the pipework and clamps from below the running board.

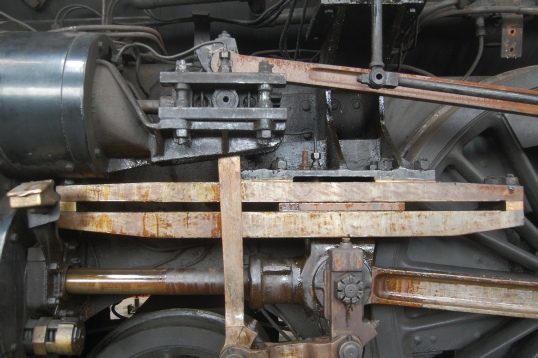

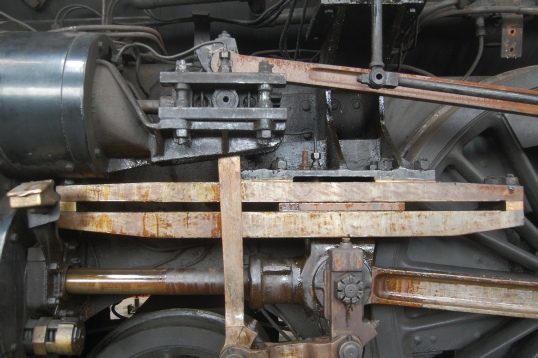

Reverser linkage.

In the background in the centre is the two-sided curved near-vertical expansion link. It is oscillated at the bottom by the return crank rod (out of shot) attached to the centre driving wheel.

At left-centre is the fluted radius rod that the driver can move up or down in the expansion link by moving a rod connected to the top of the right-angled link.

When the radius rod is below the expansion link pivot, the loco will move forwards when steam is admitted to the cylinders. Conversely, reverse is selected by lifting the radius rod above the pivot.

The round rod at left also provides a fore-and-aft motion to operate the mechanical lubricator.

19th April 2017.

In the workshop at last.

With tools and safe working equipment readily to hand, we should now be able to really start motoring.

The first objective is to establish which parts will need to go away for overhaul. It’s almost a given that the boiler will fall into this category but it needs detaching from the frames and many parts removing so that it can be thoroughly inspected.

Cylinders, Pistons and Rods and Slide bars would be difficult for us to repair/replace if that’s needed, so an early assessment of them is scheduled.

Wheels would need to go away if re- profiling is necessary, so an inspection of them is also planned.

LHS steps and front section of running board have been removed and a start has been made on removing the steam pipes.

LHS motion.

We need to know how much wear there’s been on the piston rod and on the slide bars.

26th April 2017.

Focussing on preparing for boiler removal. At the front end, steam pipes at each side of the smokebox are disconnected at the flanges that connect them to the cylinders. These nuts were extremely difficult to shift and only the application of Graham Batho’s persistence and a great deal of heat was sufficient to get them off.

Inside the smokebox, Ken and George shifted several wheelbarrow’s full of rusty soot (or was it sooty rust?) To expose the parts we need to work at. Ken sliced off one of the bolts holding the blower ring in place but time overtook him and the others await a next session.

At the other end of the loco, Alan, Graham and StanD removed all the roof fixing bolts, except for 4 in the corners (to avoid the roof coming down on their heads)

The disconnected LHS steam pipe

Note the missing nuts not holding the roof down.

27th April 2017.

Finishing off from yesterday. Pete and Stan completed removing the roof bolts (the handrail fixings proved difficult but succumbed in the end). In the afternoon, Pete moved to the smokebox and, helped by Fran, disconnected the blower pipe and blower itself, Stan cleared space alongside the loco, moving Muriel parts down to their end of the workshop. Then Dave Head and Stan used the overhead crane to lift off the cab roof and place it in the cleared space.

Smokebox cleaned out and with blower and pipe removed. Lower centre can be seen the blastpipe rising from the floor. It is directly under the petticoat (top centre).

A next job is to get the square area of floor around the blastpipe broken up. It’s made of cement and needs to be removed to free the boiler from the frames.

May 2017