6th January 2019.

Christmas and cold weather have affected progress considerably.

Highlights include very good work on one of the driving axles.

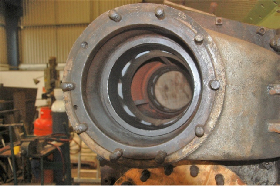

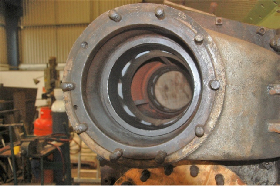

Bogie

A start has been made needle-gunning paint from one of the wheels.

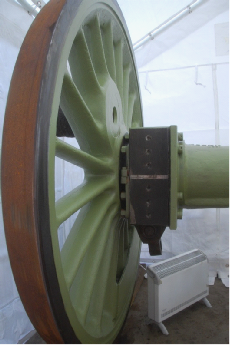

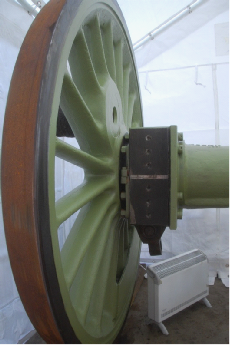

Wheels

One pair of wheels is near-ready for priming, advice from C&W is to needle-gun to remove paint, wire brush to remove surface rust, de-grease and tack-wipe, then apply primer direct to the metal. No rust-convertor or Phosphoric is necessary. Note that temperature needs to be 10 degrees or above before paint can be applied

As requested before, please don’t work on the wheels near the motion (to avoid dust etc. on the bearing surfaces)

Tender

Re-wheeled. Horn Keeps fitted. The tender is scheduled to be on-pit Wed 9th for fitting of brake rigging. New blocks are on order but will not be fitted initially.

Parts removed count:

1444

13th January 2019.

Cylinders and Motion

All studs removed from rear of LH cylinder and a start made on the RHS. New studs will be used when the covers are re-fitted. That’s 80 studs for the cylinders and 40 for the valves.

Arrangements are being made to have front RH PV bored out to give adequate clearance for in-service valve piston checking.

Wheels

One pair of wheels is ready for priming.

A gazebo has been purchased to allow a locally-warm space to be created in the workshop so that painting can be done even when it’s cold.

Tender

Re-wheeled. Horn Keeps fitted. 5 brake hangers and 2 crossbeams attached but await fitting of the remainder before tightening.

Note newly-recruited loco crew are using the tender for cleaning practice.

20th January 2019.

Cylinders and Motion

All cylinder studs now removed from rear of both cylinders. Next step is to clean out holes and run a tap down to rectify any thread damage.

Contrary to the suggestion in the last report, only the rear studs are to be replaced – those at the front are in much better condition.

Bryn Engineering will be at Wansford Wed/Thur/Friday to bore out front RH PV.

Wheels

The gazebo has been erected and test-heated to confirm that a 2KW heater, on a low setting, is sufficient to maintain a temperature above 10oC.

One pair of wheels is de-greased and is ready for priming.

Tender

Practically complete except for brake adjusters and brake blocks. Brake blocks are expected this week.

Grover washers for brake adjusters will be replaced by a second lock-nut.

Axlebox cover gaskets are part-fitted.

Boiler

CME will be speaking to our insurers this week to clarify how we can select people to undertake testing procedures to establish weldability of firebox wrapper.

Frames

Work has started on the removal (for repair) of the damaged upper stretcher.

The collection of bushes and pins is growing.

A start has been made on making a jig to aid the construction of a replacement stretcher for the badly-corroded one that was removed from below the firebox.

27th January 2019.

Cylinders and Motion

As expected, Bryn Engineering visited to bore out the front RH PV.

Rear main cylinder stud-hole cleanout has started.

Replacement stud manufacture – Experiment in progress to understand feasibility of making studs off-site.

Driving Wheels

Great success in the gazebo. The paint team and one of the wheels team got a coat of primer applied to two wheels and axle-box in a single day.

The other wheels are half-stripped and have been turned to allow the second half to be completed next session

Pipes and fittings

Fitters have dismantled the exhaust steam injector and internal parts are being appraised for repair or replacement.

Boiler

Still no clarity on way forward although discussion with new insurers was very positive and they agree that the weldability assessment can be detached from the placing of the overall contract.

Frames

Work continues on the removal (for repair) of the damaged upper stretcher, the mid-stretcher rivets have been drilled through.

December 2018

December 2018