4th October 2017.

A good day. Started off wanting to get everyone attacking the boiler - it's the most urgent item and keen to make as much progress as we can. It quickly became apparent that it's not possible to deploy too many hands in such a confined space, especially when noise and heat are both involved. So Graham and Alan concentrated in the firebox, removing the grate supports, while Jamie and (another) Alan punched out rivets holding the smokebox to the boiler. Yesterday the boiler inspector, at the railway to look at the steam crane, was collared and the latest set of thickness figures from 73050's boiler run past him. As expected he said there was no point in going further - both tapered and parallel sections need replacement. So the urgency is now to get the firebox and both tubeplates assessed. At the front end, the quickest way to do this is to remove the smokebox, making tube extraction much easier. At the back end, we need to start cleaning out the firebox. In the afternoon, new Alan made good progress on the resistant flaking rust on the firebox RHS, while old Alan was replaced by Ian and David helping Jamie.

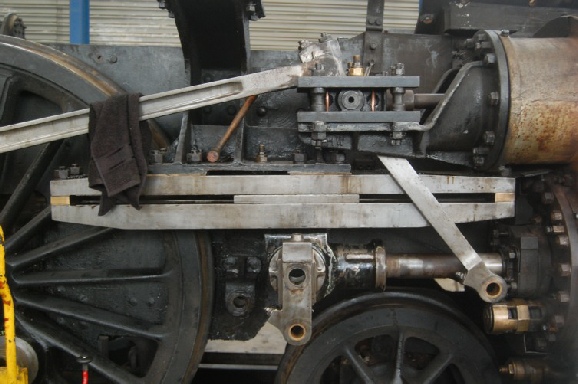

After the false-start, chassis teams resumed their normal tasks and at the rear, Ian Ddavid and Philip made some progress towards getting brake actuation down - the steam brake cylinder is off the loco and it's hoped that the lever and bracket will follow next week. At the front end, John Wood and Wootton with Geoff continued the pipe chase, moving beyond the bogie with about 10 thin (lub) and 3 thick (steam/vac) pipes moved to the container. Also removed was the annulus that holds the bogie to the frame - so now if the frames are lifted, the bogie should remain on the track. In the centre of the loco, Ian and David freed the centre sandbox, lifted it down to the workshop floor and removed all 4 "udders".

Unaffected by outside panics, Paul Ken and Stan took the front off the RH cylinder. Wear inside looks not-too-bad, the piston has dropped to sit on the cylinder 'floor', suggesting that the rings have lost their springiness although there are still fore-and-aft movement lines on the cylinder ceiling. Some very light scoring is apparent at 3 and 9 o'clock and it looks as if the front ring has broken between 1130 and 1230.

Also impervious to the outside excitement, Graham and Clifford continued cleaning and overhauling the airpump.

David and Ian review the sate of the sandbox that they’ve just taken down. It’s upside down and three of the ‘udders’ have been removed, exposing the holes through which sand flows to the wheels, the fourth udder (top, right) awaits removal.

September 2017

September 2017